New Micro-nano Insulating Brick

Description

Inquiry

Related products

Description

1.The description of New Micro-nano Insulating Brick Series:The new micro-nano insulating brick series products solve the needs of thermal insulation of the wall and bottom of various large furnaces, and the working temperature can be from 600°C to 1400°C.

With a wide range of application, good thermal insulation performance and high strength,the product can meet the requirements of energy saving and environmental protection of various furnaces.

(1) Main advantages and features

(a) Low thermal conductivity:With low thermal conductivity, it has good heat insulation effect and can make the furnace wall thickness thinner under the same temperature condition, thus saving more cost.

(b) Low heat capacity:Due to its ultra-light bulk density and low thermal conductivity, the insulating brick accumulates less heat inside, making it more energy efficient.

(c)Good stability:With very low iron oxide and alkali metal content, its stability is better within the specified service temperature.

(d) High strength: Its strength at normal and high temperatures is higher than other products with the same bulk density at the same temperature.

(e)Low size tolerance:The size tolerance is within 0.05mm, the dimensions can be customized according to customer requirements.

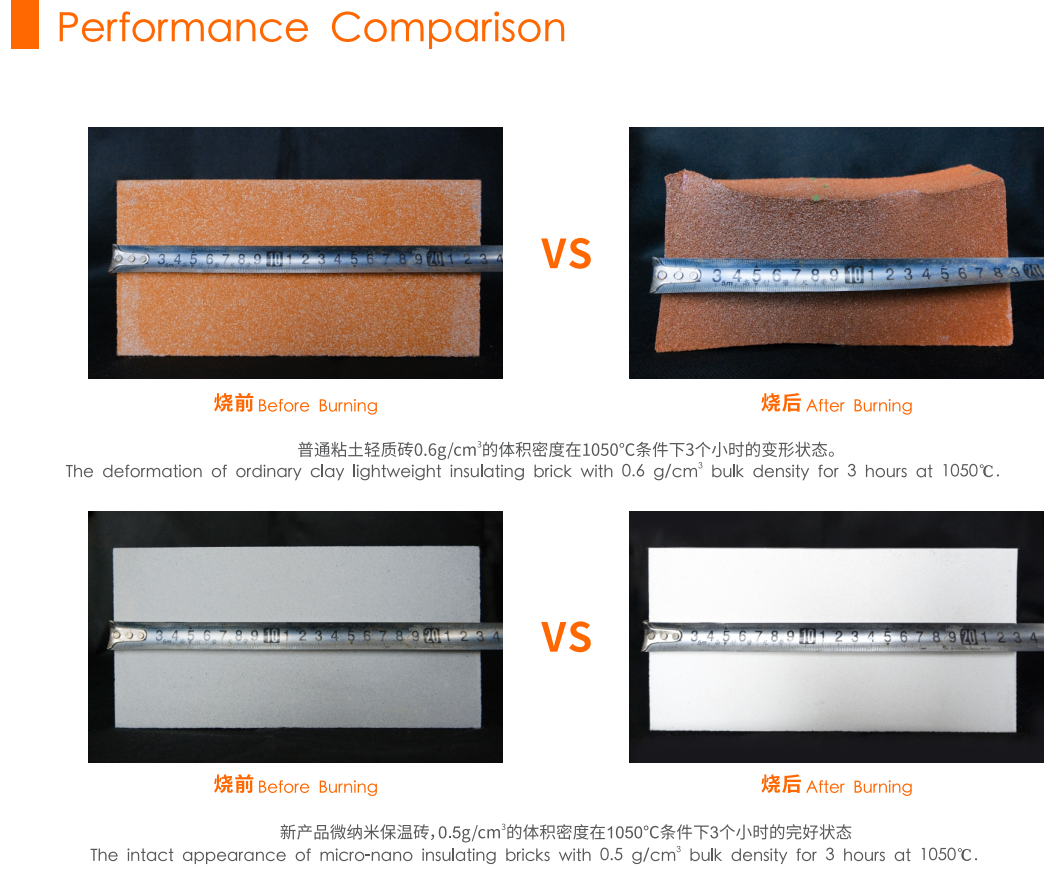

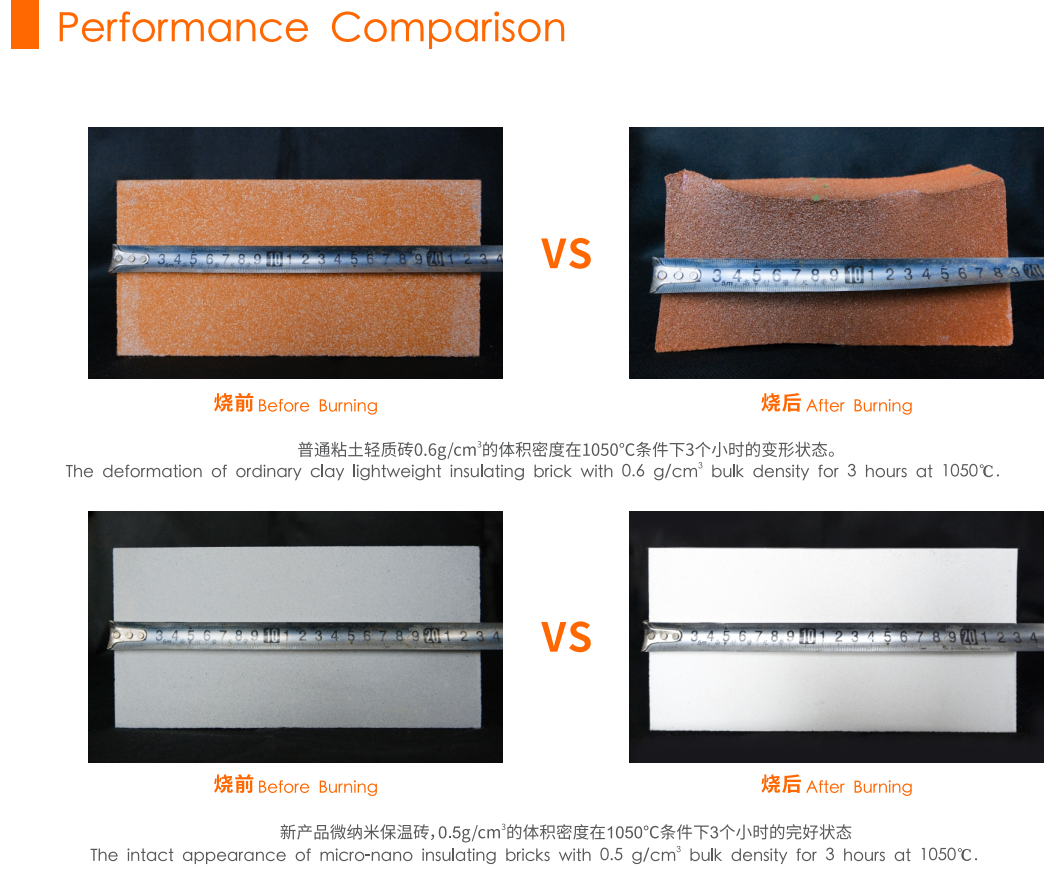

2.Performance Comparison

After the ordinary clay lightweight insulating brick with a bulk density of 0.6 g/m3 and the micro-nano insulating brick with a bulk density of 0.5 g/m3 were burned simultaneously at 1050℃ for 3 hours, the ordinary clay lightweight insulating brick shrank from 230mm to 190mm and the brick was severely deformed, while the micto-nano insulating brick did not change in size and its appearance was intact.

After the ordinary clay lightweight insulating brick with a bulk density of 0.6 g/m3 and the micro-nano insulating brick with a bulk density of 0.5 g/m3 were burned simultaneously at 1050℃ for 3 hours, the ordinary clay lightweight insulating brick shrank from 230mm to 190mm and the brick was severely deformed, while the micto-nano insulating brick did not change in size and its appearance was intact.

4.The Technique Data of New Micro-nano Refractory Insulating Brick:

2.Performance Comparison

After the ordinary clay lightweight insulating brick with a bulk density of 0.6 g/m3 and the micro-nano insulating brick with a bulk density of 0.5 g/m3 were burned simultaneously at 1050℃ for 3 hours, the ordinary clay lightweight insulating brick shrank from 230mm to 190mm and the brick was severely deformed, while the micto-nano insulating brick did not change in size and its appearance was intact.

After the ordinary clay lightweight insulating brick with a bulk density of 0.6 g/m3 and the micro-nano insulating brick with a bulk density of 0.5 g/m3 were burned simultaneously at 1050℃ for 3 hours, the ordinary clay lightweight insulating brick shrank from 230mm to 190mm and the brick was severely deformed, while the micto-nano insulating brick did not change in size and its appearance was intact.3.Benefit Analysis of the micro-nano insulating bricks:

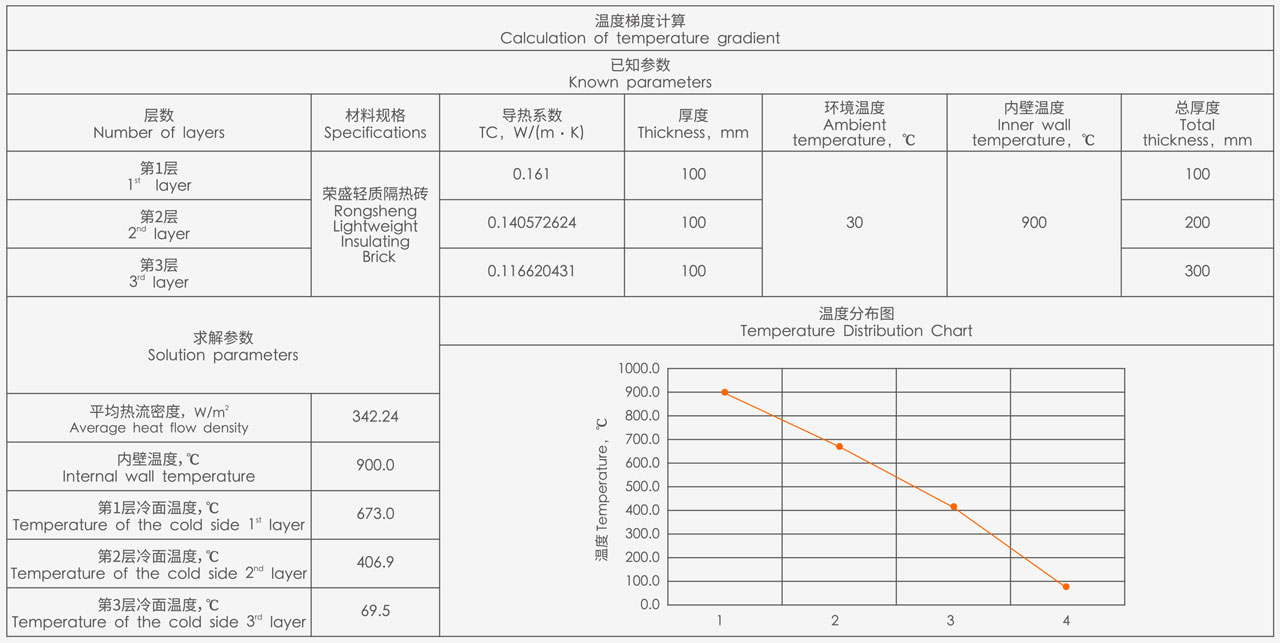

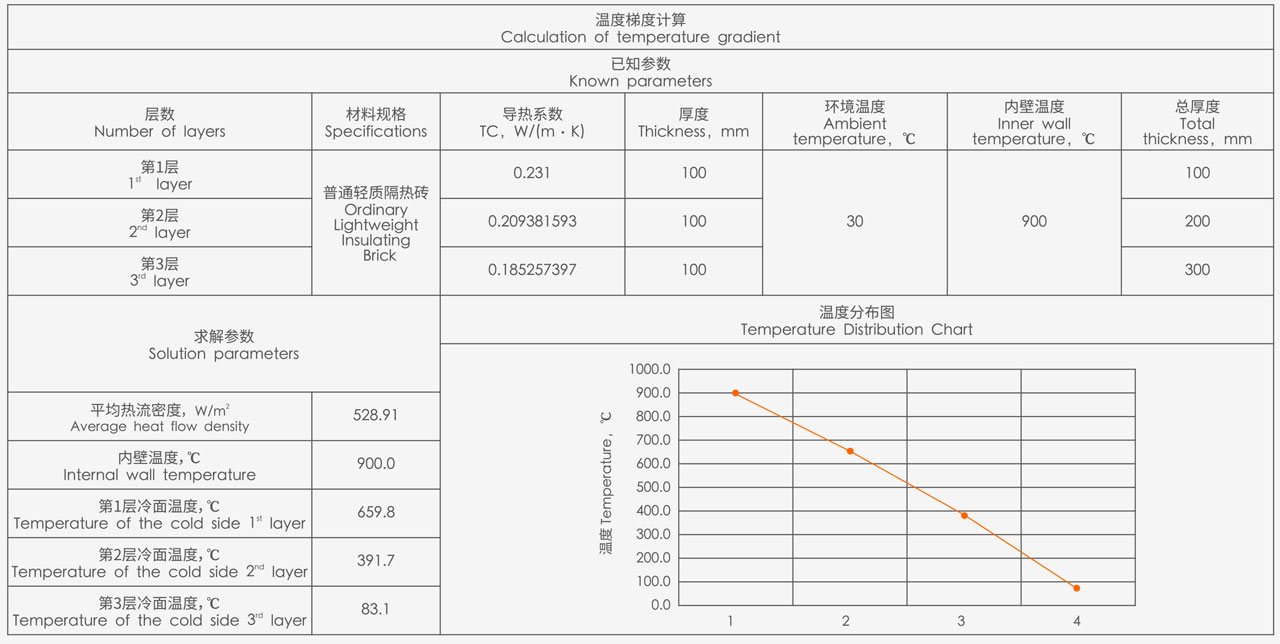

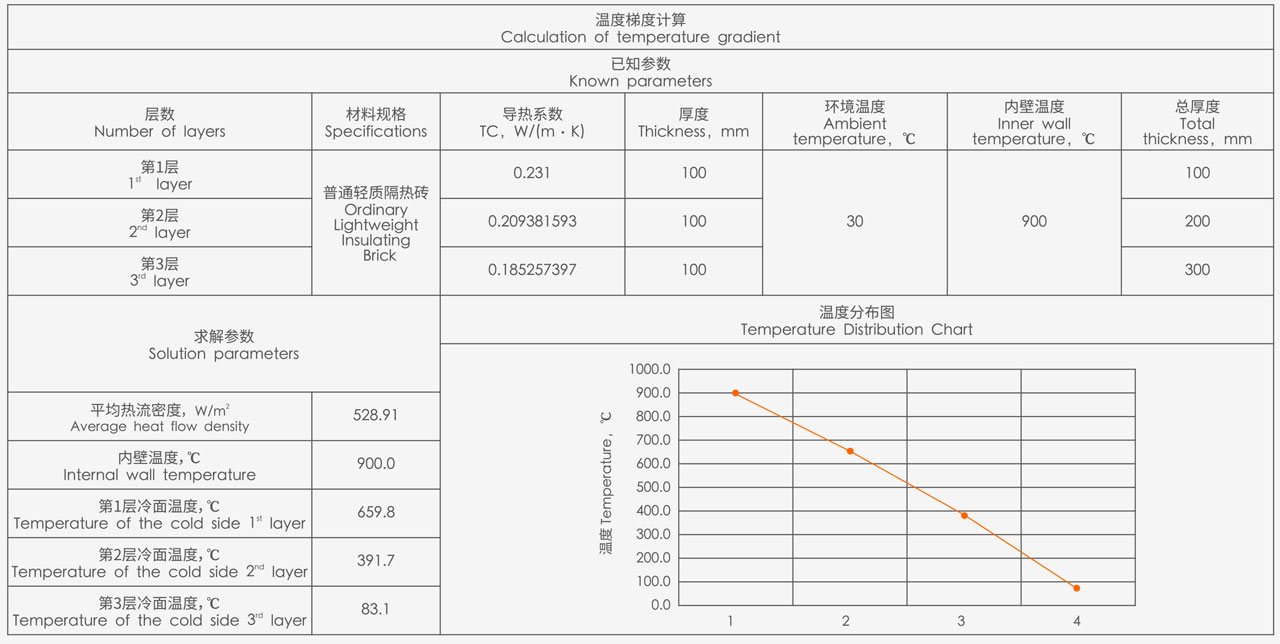

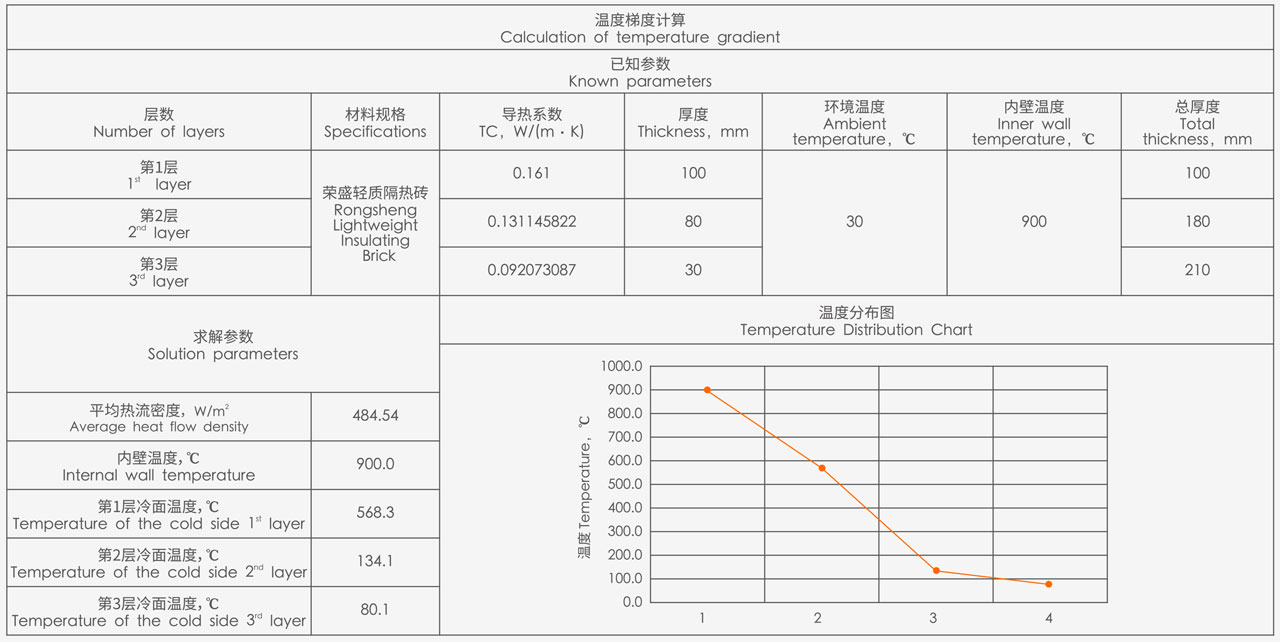

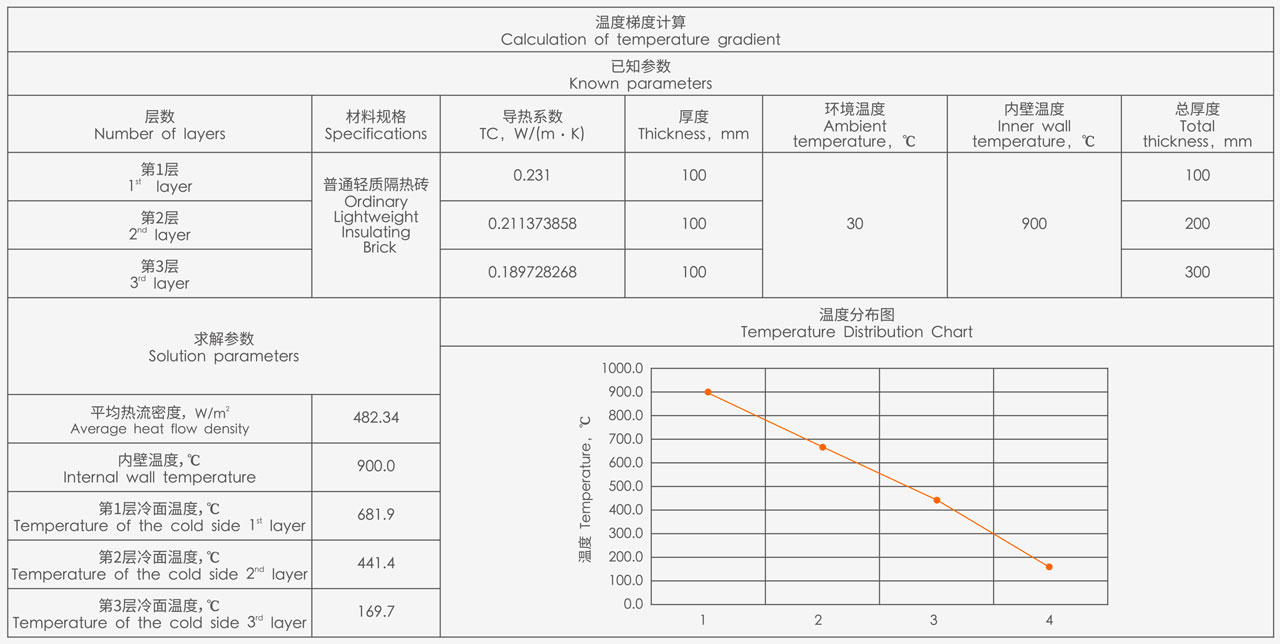

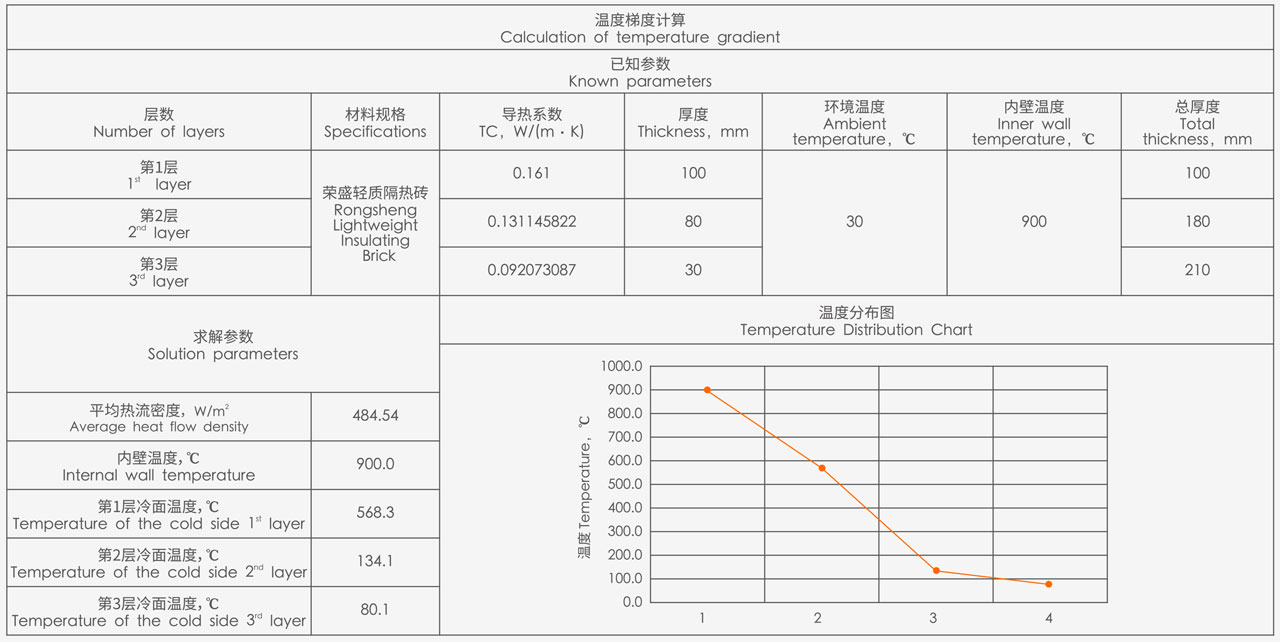

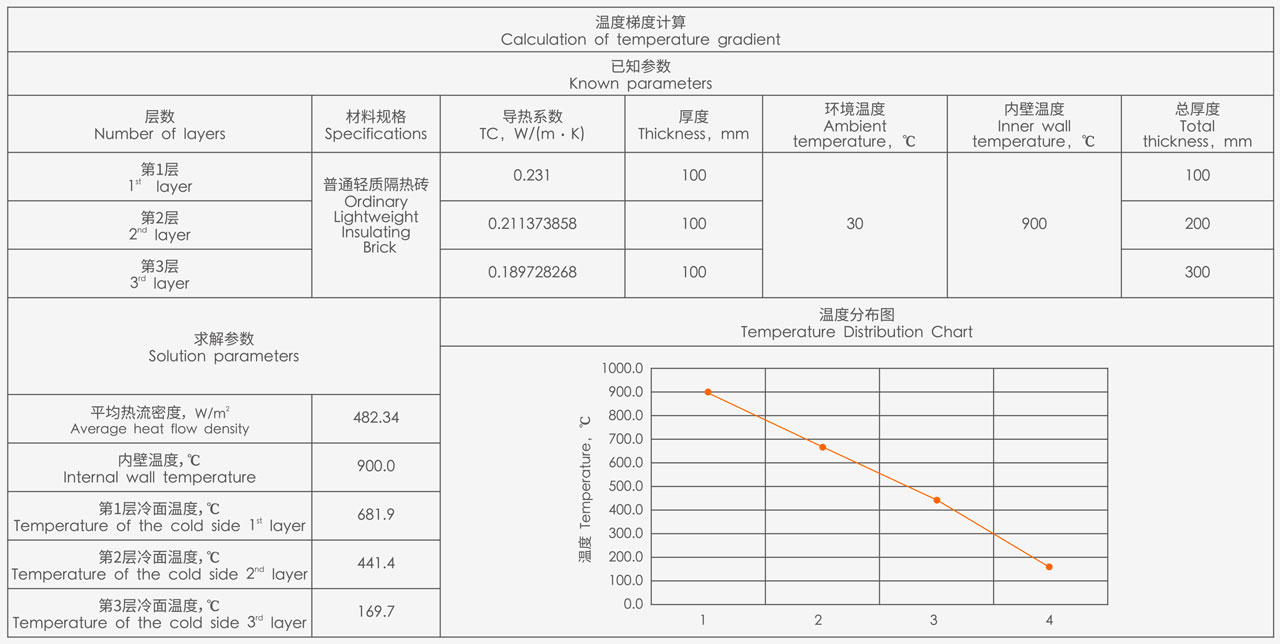

Assuming that the temperature inside the furnace is 900°C, the temperature of the external environment is 30°C, and under the condition of no wind, compare the temperature difference between the outer wall of the same 300mm thickness of 1000 type lightweight insulating bricks and the same price of ordinary lightweight insulating bricks as refractory insulating layer,and compare the thickness difference of the furnace wall of both materials when the outer wall temperature reaches 80°C, the detailed comparison parameters are as follows:

(1)When the wall thickness is all 300mm:

The actual measured data when the wall thickness of two different materials is 300mm, the data are compared as follows:

The actual measured data when the wall thickness of two different materials is 300mm, the data are compared as follows:

a. With Rongsheng lightweight thermal insulation bricks, the temperature of the outer wall is 70°C (low);

b. With ordinary lightweight heat-insulating bricks, the outside wall temperature is 83°C (high).

The difference of outside wall temperature: 13°C↓.

Conclusion: Rongsheng lightweight thermal insulation bricks reduce the outer wall temperature by 18.57%↓.

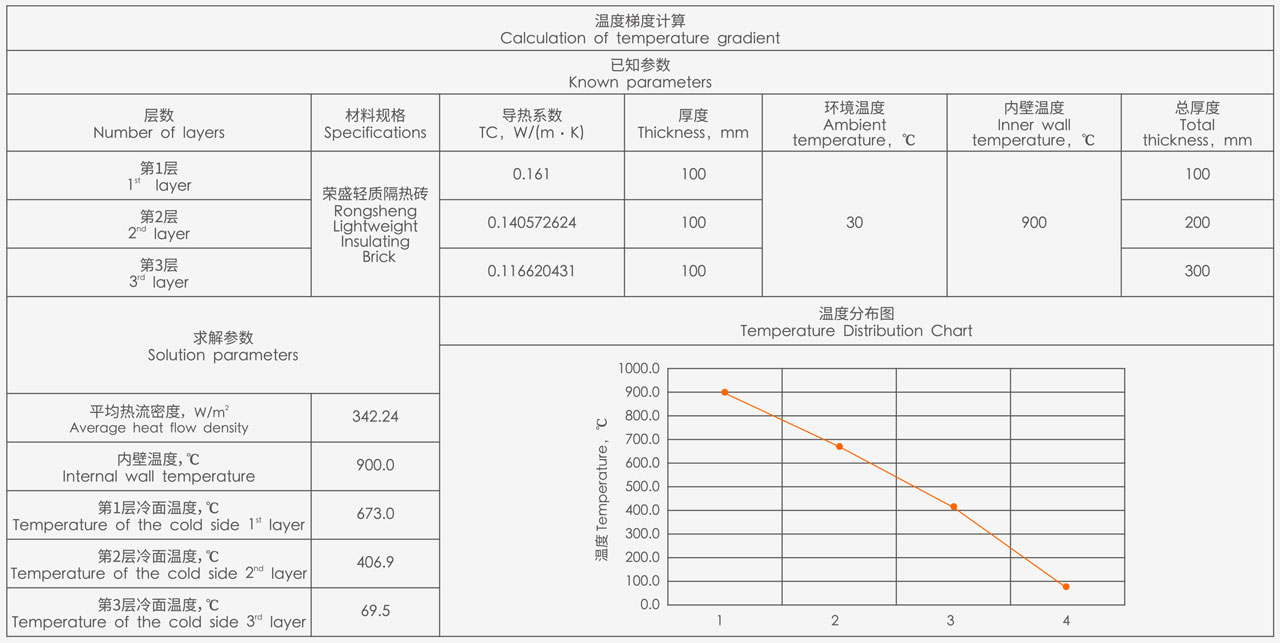

(2)When the outside wall temperature is 80°C:

The actual measured data, when the temperature of the outside wall reaches 80°C, the data are compared as follows:

The actual measured data, when the temperature of the outside wall reaches 80°C, the data are compared as follows:

The actual measured data, when the temperature of the outside wall reaches 80°C, the data are compared as follows:

The actual measured data, when the temperature of the outside wall reaches 80°C, the data are compared as follows:1.Using Rongsheng light-weight thermal insulation bricks, only 210mm thick (thin) is needed;

2.Using ordinary light-weight thermal insulation bricks, 330mm thick (thick) is needed.

The difference of wall thickness: 120mm↓.

Conclusion: Rongsheng light-weight thermal insulation bricks reduce the thickness of furnace wall by 57.14%↓.

4.The Technique Data of New Micro-nano Refractory Insulating Brick:

| Item | Index | ||||

| Model | RS-WNM0.25 | RS-WNM0.35 | RS-WNM0.4 | RS-WNM0.45 | RS-WNM0.5 |

| BD,g/cm3 | 0.25 | 0.35 | 0.4 | 0.45 | 0.5 |

| CCS,MPa | ≥0.5 | ≥0.6 | ≥0.8 | ≥1.0 | ≥2.2 |

| TC,W/(m.K) | ≤0.1 | ≤0.105 | ≤0.110 | ≤0.115 | ≤0.119 |

| PLC,% | ±0.5 | ±0.5 | ±0.5 | ±0.5 | ±0.5 |

| 600℃*12h | 900℃*12h | 1000℃*12h | 1050℃*12h | 1050℃*12h | |

| Fe2O3,% | ≤0.5 | ≤0.5 | ≤0.5 | ≤0.5 | ≤0.5 |

5.Typical Applications

It can be used as a thermal insulation backing layer of refractory materials, and the application include: all kinds of industrial furnaces, hot blast furnaces, heating furnaces, smelting furnaces, flue pipes, hot air ducts and other heating and heat generating parts.

(a) Roller kilns Tunnel kiln

Application: Furnace walls and bottom insulation layer of the ceramic roller kiln.

Alternative of following: Lightweight clay brick, high alumina insulating brick, mullite insulating brick.

Advantages: not easy to shrink, not easy to pulverize, performance not easy to decay, more cost-effective.

(b)Large Hot Air Duct

Application position: Insulation layer of large hot air duct.

Alternative of following: Lightweight clay bricks, high alumina poly-light bricks

Advantages: lower outside wall temperature, more energy efficient, lighter weight of thermal equipment more cost effective.

Request For Quotation

You can get the price list and we will contact you within one working day.

+86 13526662273

Case

Our Refractory Bricks Are Exported to Egypt

GIFA 2019

Great Job Done for South Africa Customer

South Korean Customer and Indonesian Customer Visit

Are you interested in our offer?

Contact us!10th Floor, No. 6 Building, China Central Electronic CommercePort Daxue Road, Zhengzhou, Henan

Copyright @ ZHENGZHOU RONGSHENG REFRACTORY CO., LTD. All rights reserved site map/site index